Day 02 – How We “Jungle”

09/07/2021

I am an industrial designer. This phrase is usually followed by one of two things: 1) a long pause, after which I just say “I design products” or 2) “ah, okay” with the courtesy head nod and the obligatory “what’s that?” In all honesty, both conversations end the same way because there’s no easy way to explain what industrial design is. I suppose upon a little reflection, it’s like telling someone you work in a museum before walking away without another word. The mind is left to wander and free to imagine the possibilities of what that means. Perhaps a better way of viewing what industrial design is would be to think of it as the MacGyver of the design world (cue theme music below) – you really could do anything with it. It’s such a broad field and, more often than not, an industrial designer will rely on several different skills in their design toolbelt in the course of completing a single project. MacGyver!

Still not clear? Well, I’ve created an example just for explanation purposes to help walk you through the industrial design approach and, ultimately, the method we’ll use at Dream Jungle Studios.

Suppose a dentist has a group of patients that always seem to have trouble brushing their teeth. Maybe this is a group of kids who always use too much toothpaste and make a complete mess of their bathrooms every time they’re left alone with the tube (bear with me; keep in mind this is just an example). So, we’re going to help our dentist friend by designing a better toothbrush for this situation and possibly come across a few other opportunities in the process. You can follow along on the right column below to see how we might go about solving the issue.

RESEARCH

First step is RESEARCH. The purpose here is to explore the environment, learn about the user to gain a better understanding of the situation, and hopefully identify which issue(s) can be addressed with a solution. It’s also where we’ll see what other items are nearby and how the user and items all interacts together in the environment. Research is very important and will be circled back on at different points throughout as needed. When done well, it makes the next stage a lot easier. Various experts in the field of interest, as well as those in related fields, may be contacted to get a comprehensive analysis of the situation and to gain the best perspective before digging in.

For our example, we’ll keep things simple. The kids are preschool age and items near the sink include soap, a hand towel, a toothbrush, and a tube of toothpaste.

A research of patents would be conducted to find anything similar being developed in the market.

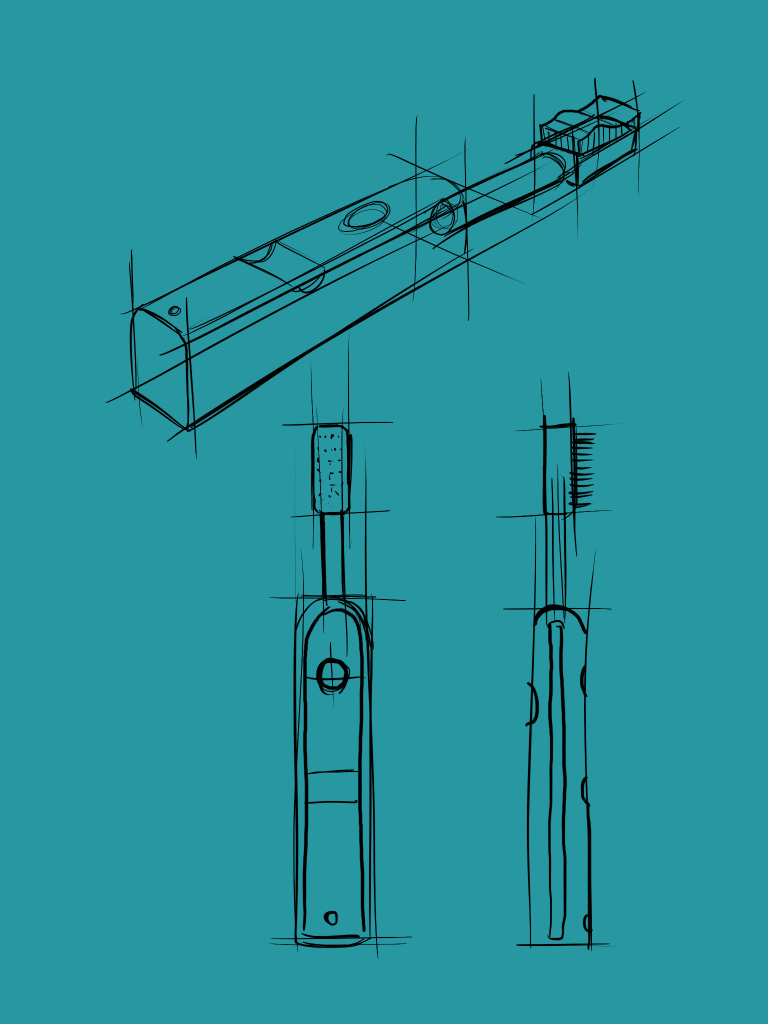

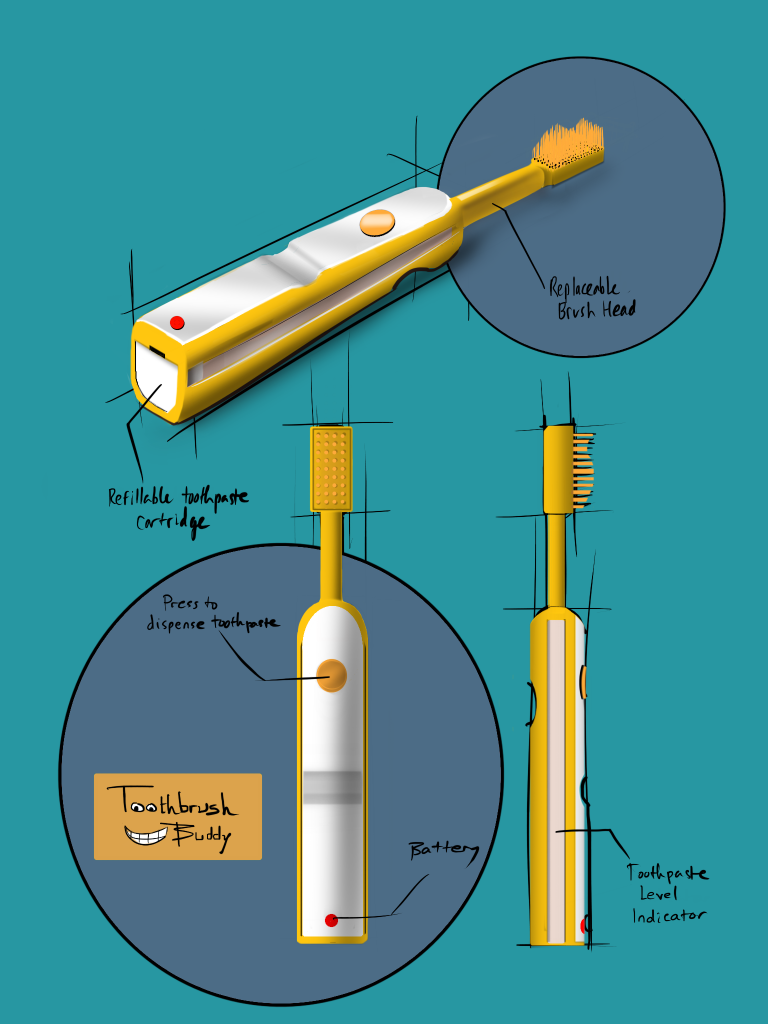

CONCEPT DEVELOPMENT

Next step is CONCEPT DEVELOPMENT. This is perhaps the most engaging part of the process because here is where an industrial designer gets to flex their mind while drawing upon their imagination and ingenuity. Here is where we brainstorm, sketch, explore concepts, and work through the solution. Development includes matching the solution to the user and environment and will often be inspired by a certain aesthetic. The designer might create a mood board to inform their design choices. This will involve some exploration into colors, materials, and finishes (CMF) as well as a deeper understanding of the end user. Additionally, the development takes the user experience into consideration (a step-by-step walkthrough of how the product might be used).

The product will live in a bathroom and will be around a lot of water where it also has a probability of becoming submerged.

This tells us we want to build something sturdy, that can be used on a regular basis. We’ll need the body frame of the item to be waterproof and durable enough to handle hard falls.

We want our toothbrush to be sustainable so that it doesn’t end up in a landfill, at least not easily.

We’ll design it so that it has a built-in rechargeable battery and the brush head is replaceable to reduce waste and extend the life of our brush.

To address the concerns of the dentist, we create a toothbrush that will automatically dispense the correct amount of toothpaste directly to the brush head.

We decide to combine two products into one by adding a reloadable toothpaste chamber that gets inserted into the handle. The single button on the front dispenses a small bead of toothpaste to the brush when pressed. A built-in timer prevents the kid from trying to dispense additional paste (a parental override can allow it to be reset). A battery indicator doubles as an error light to aid with troubleshooting any issues.

BUILD / MANUFACTURING

Depending on the project, this step will either result in a one-off BUILD (customized item) or a product ready for MANUFACTURING (mass production). Not to get too far ahead of ourselves, there are still a few elements of development at this stage. A product’s complexity may require an engineer to work out the mechanics of how the item will function and, in conjunction with a manufacturer, will assist with determining construction feasibility. Other advisors relevant to the product may be consulted during this stage (these same experts would have been contacted in our research phase as well). Before finalizing the product, a form study might be performed to ensure the item fits comfortably in the user’s hands (or interacts easily with whatever body part the product is designed for). It isn’t uncommon for the design to evolve over the course of a few prototype iterations. These physical models are important as they improve the odds that the final construction will meet specifications.

We look at the average size of the user’s hands and do a quick form study using foam material. This model might also be constructed in CAD and printed with a 3D printer. The important thing is getting an object that can be handled and interacted with physically.

A physical model is presented to one of the kids in our targeted user group. We find the object is too small and the handle is uncomfortable and slippery. We modify and retest until we find the right combination of size and material.

Our engineering contact give us a quote to develop the toothpaste cartridge mechanism as well as the computer chip for dispensing the toothpaste. There may be additional information here that can steer the design – maybe a high component cost causes a change in one of our features (after all, affordability is usually a very important consideration). Maybe the handle needs to be revised so the battery fits.

We consult the dentist and end user about the type of toothpastes needed (flavors, strengths, etc.)

We consult with the toothpaste supplier to secure the toothpaste needed for our cartridges.

A CAD model is created to send to our manufacturing partner, who informs us of the cost and says it will take six weeks to create the mold for producing our different toothbrush parts.

BRANDING (MARKETING)

If this is a product being developed for mass production, BRANDING and MARKETING will require heavy consideration from logos and colors all the way down to packaging and distribution. Whereas an established company will already be handling these concerns using internal resources, a new company with an item just entering the market might need a complete development of their brand. A product could successfully gain exposure through word of mouth within it’s respective industry, so marketing and advertising are handled in relation to the scenario.

A brand is very important when establishing your company alongside a competitor or even introducing a new product into the marketplace.

After introducing the product to a very positive reception, we consult with the dentist who decides to sell the entire product line to Proctor & Gamble. P&G is able use their vast resources to produce each toothbrush more efficiently and distribute to an international market under their easily recognizable brand name.

END GAME

Thank you for sticking around to the end. Hopefully the toothbrush example helps shed some light on what it is an industrial designer does. What we do. What I do. Bear in mind, I’m speaking as a newbie on a few items here, so please don’t roast me for my knowledge. I’ll admit, there are some components within the process that are going to be a learning process and even challenging. However, the steps and methodology contained within this article are how Dream Jungle Studios plans to handle the projects we work on and I have no doubt our perseverance will guide us through it all. Now seriously, go check out MacGyver (the original series from the 80s & 90s; I can’t speak to the quality of the newer version).

Dream Big. Jungle On.